Optimizing warehouse operations is crucial for companies to stay competitive in today’s fast-paced business environment. Custom warehouse automation solutions play a vital role in streamlining processes, increasing efficiency, and improving overall productivity. CIMC Pteris, a leading provider of custom warehouse automation solutions, specializes in delivering innovative and tailored systems to meet the unique needs of various industries.

Revolutionizing Warehousing Operations with Stacker

The stacker is a game-changer in high-rise shelf warehouses, offering exceptional functionality and application flexibility. This automated solution revolutionizes warehousing operations in several ways.

Increased Automation and Efficiency: By utilizing automated stackers, companies can significantly enhance their automation levels and overall efficiency. These stackers minimize the need for manual intervention, reducing the risk of errors and delays.

Large Loading Capacity and Versatility: Automated stackers boast large loading capacities and can navigate through narrow aisles, maximizing storage space utilization. They can handle heavy loads efficiently, making them suitable for a wide range of applications. Whether it’s lifting and transporting pallets or stacking goods, stackers excel in various warehouse tasks.

Streamlining Warehouse Processes with (DE)palletizing Systems

The robot-based (DE)palletizing system offered by CIMC Pteris plays a pivotal role in streamlining warehouse processes and optimizing labor utilization. This system offers significant benefits to companies in various industries.

Improved Efficiency and Accuracy: By employing robots for palletizing and depalletizing operations, companies can achieve improved efficiency and accuracy. These robotic systems excel in handling fragile or delicate items, minimizing the risk of damage during palletizing. They can precisely place items on pallets, ensuring accuracy in stacking and arrangement.

Reduction in Labor Costs and Industrial Accidents: Robot-based (DE)palletizing systems reduce labor costs by eliminating the need for manual handling of goods. This automation reduces dependency on human labor and frees up resources for other value-added tasks.

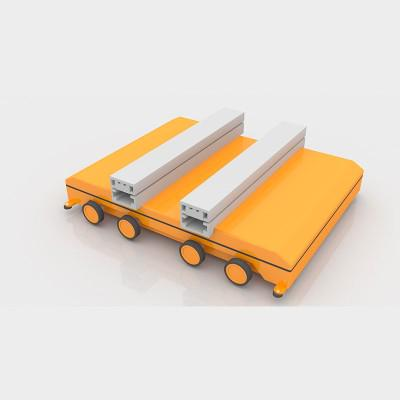

Optimizing Space Usage with the Four-way Shuttle System

Efficient space utilization is a critical aspect of warehouse management, and CIMC Pteris addresses this challenge with the four-way shuttle system. This system optimizes space usage and offers numerous advantages.

Optimal Space Utilization and Storage Efficiency: The four-way shuttle system efficiently stores and retrieves goods, eliminating wasted space within the warehouse. By utilizing racks and automated shuttles to transport goods horizontally and vertically, this system maximizes storage efficiency, allowing companies to utilize their warehouse space to its fullest potential.

Streamlined Operations and Improved Productivity: By minimizing manual handling and streamlining operations, the four-way shuttle system significantly improves productivity. Automated shuttles efficiently move goods within the warehouse, reducing the time required for storage and retrieval. This automation allows warehouse staff to focus on higher-value tasks, enhancing overall productivity.

Conclusion

Custom warehouse automation solutions are essential for enhancing efficiency and productivity in today’s competitive business landscape. CIMC Pteris, a leading provider of custom warehouse automation solutions, offers innovative systems tailored to meet the unique requirements of various industries. With solutions like stackers, robot-based (DE)palletizing systems, and the four-way shuttle system, CIMC Pteris empowers companies to optimize their operations, reduce costs, and embrace the future of warehouse automation. Partnering with CIMC Pteris ensures access to cutting-edge technology and a commitment to delivering customized solutions that drive business success.