In today’s fast-paced business environment, efficient and automated warehousing solutions are crucial for optimizing operations and maintaining a competitive edge. As an industry-leading automated storage system provider, CIMC Pteris is revolutionizing the way warehouses operate with their cutting-edge solutions. Let’s explore some of our innovative products and services that are enhancing efficiency and safety in warehousing.

Automated Stacker: Enhancing Efficiency and Safety in Warehousing

CIMC Pteris’ automated stackers are designed to streamline warehouse operations with their advanced automation capabilities. These stackers run along the track in the roadway of high-rise shelf warehouses, accessing unit goods to complete efficient in-out operations. The advantages of CIMC Pteris’ automated stacker solutions are manifold. They offer a high degree of automation, enabling warehouses to achieve seamless and error-free operations. With large loading capacity and a wide range of applications, these stackers can handle diverse goods with ease.

The application scenarios for automated stackers are vast, benefiting warehouses, factories, and ports alike. By implementing automated stackers, these facilities can improve circulation capacity, increase productivity, and enhance logistics transportation. The automated stackers enable faster and more precise handling of goods, reducing the time required for loading and unloading operations. This leads to improved overall efficiency, reduced labor costs, and enhanced safety within the warehouse environment.

Robot of (DE)palletizing System: Streamlining Warehouse Operations

Our leading automated storage system provider CIMC Pteris’ robot of (DE)palletizing system is another game-changer in the warehousing industry. This system runs along the track in the laneway of high-rise shelf warehouses, facilitating the smooth in and out of goods. The robot of (DE)palletizing system offers exceptional efficiency and space utilization, making it a valuable asset for warehouses seeking to optimize their operations.

By implementing this system, warehouses can significantly reduce labor costs and improve productivity. The robot of (DE)palletizing system handles goods with precision, ensuring accurate and efficient palletization and depalletization processes. This eliminates the need for manual labor, reducing the risk of errors and injuries. Various industries can benefit from this system, as it enables improved goods storage and handling, reduced labor costs, and enhanced safety measures.

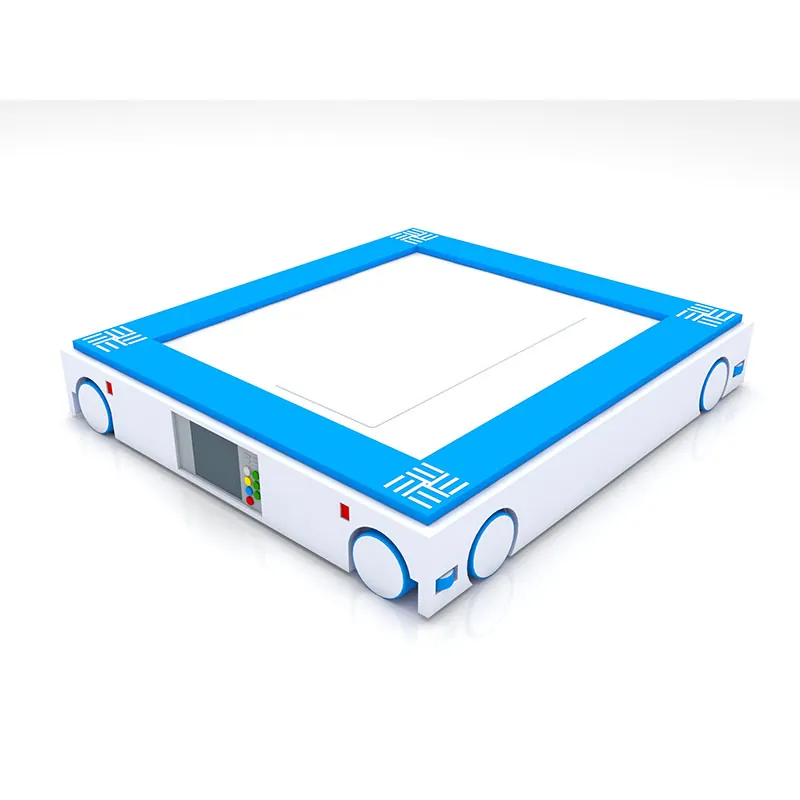

Four-way Shuttle System: Optimizing Space Usage in Warehousing

Space utilization is a critical factor in warehouse design and operation. CIMC Pteris addresses this challenge with their innovative four-way shuttle system. This system drives along vertical or horizontal orbits on cross-tracks, optimizing space usage ratios in warehouses.

Conclusion

In conclusion, CIMC Pteris, as a leading automated storage system provider, is revolutionizing warehouse automation solutions with our innovative products and services. Their automated stackers, robot of (DE)palletizing system, and four-way shuttle system are transforming the way warehouses operate, enhancing efficiency, and ensuring the safety of operations. By partnering with CIMC Pteris, warehouses can optimize their space utilization, improve productivity, reduce labor costs, and gain a competitive edge in the market. CIMC Pteris is a trusted name in the industry, known for their commitment to delivering high-quality and reliable warehouse automation solutions.