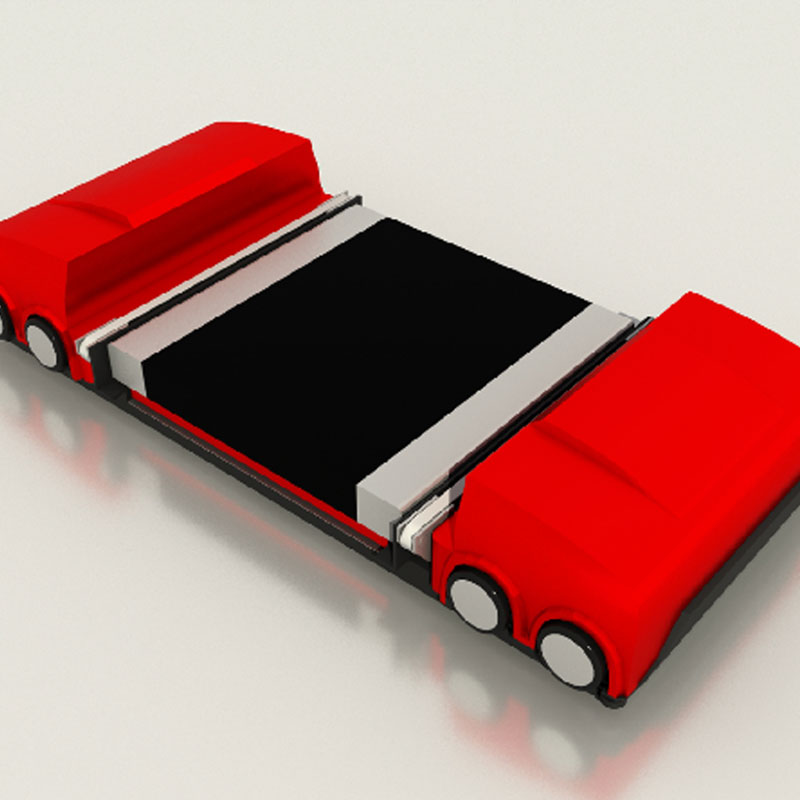

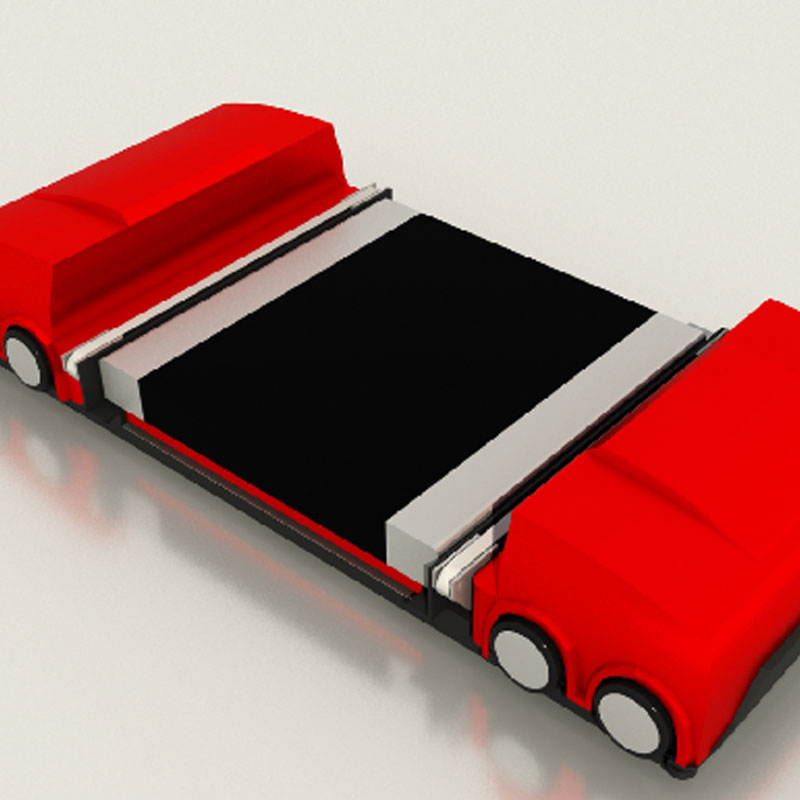

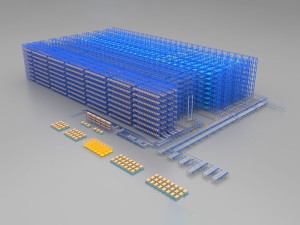

Application method: Mother-to-child shuttle car system is usually composed of subcar, mother-to-child car, hoist, conveyor or AGV, dense storage shelf and WMS, WCS system; The overall system is flexible, flexible and expandable. The storage space utilization rate is as high as 95%. It can realize the 24-hour fully automated operation of the storage system and the digital management of the whole process.

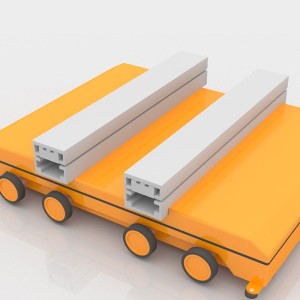

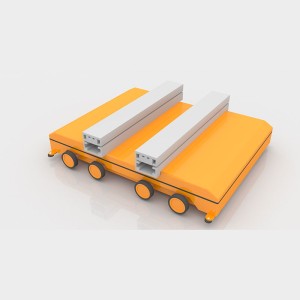

Shuttle and Carrier System (Two-Way)

Description

Descripition

Specification

Solutions

Case

Application Method:

Mother-to-child shuttle car system is usually composed of subcar, mother-to-child car, hoist, conveyor or AGV, dense storage shelf and WMS, WCS system; The overall system is flexible, flexible and expandable. The storage space utilization rate is as high as 95%. It can realize the 24-hour fully automated operation of the storage system and the digital management of the whole process.

| Specification | |

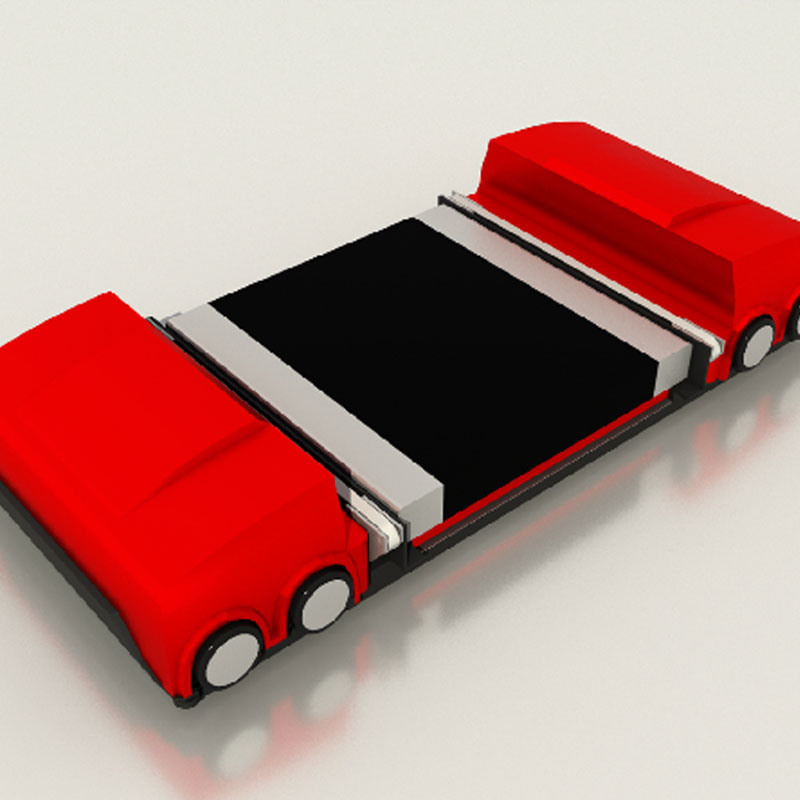

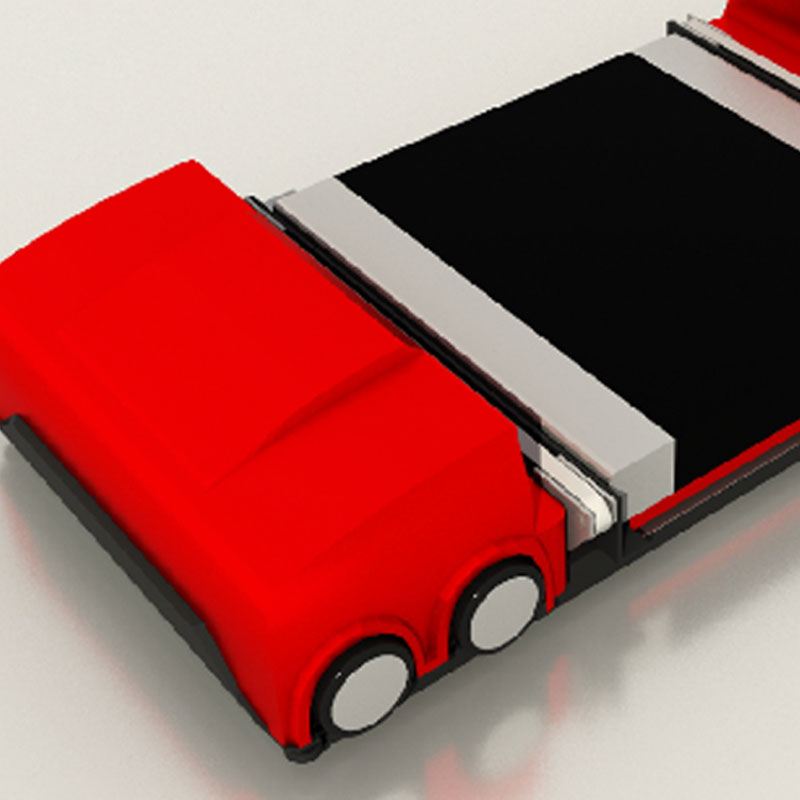

Mother carrier (empty) | 120m/min; |

Mother carrier (fully loaded) | 90m/min |

Subsidiary carrier | empty:60m/min; Fully loaded:48m/min |

Mother carrier loading/unloading speed | 12m/min |

Warehouse Automation System Solutions

With the rapid development of the enterprise, the variety of products, and the accelerated turnover of material storage, the logistics and storage space of the enterprise is beginning to be tight. Therefore, various material storage projects have become an inevitable measure for enterprises to improve efficiency and core competitiveness. PGSL merged into the airport logistics sector of CIMC Group through reverse acquisition, integrated CIMC Group’s warehousing project resources and products, and provided customers with a package of logistics and warehousing solutions.

Home Industry

-Overcoming the difficulties of automatic sorting in the home industry, realizing automatic sorting and direct loading.

-Realizing the fully automatic connection between the 5 workshops and automated warehouses.

-Realizing the off-site loading of products with various specifications, such as sofas, mattresses, and panel furniture.

-WMS: Customized the link management between multiple warehouses and locations (five logistics centers and 35 subsidiary warehouses).

Foxconn

This project consists of 6 subsystems: AS/RS Unit-load warehouse racking system, Mini-load warehouse racking system, electronic label seeding racking system, conveying system, electrical control system ECS, and dispatching system WCS. According to customer requirements, a number of customized software systems have been developed to meet the high standards of the electronics industry.