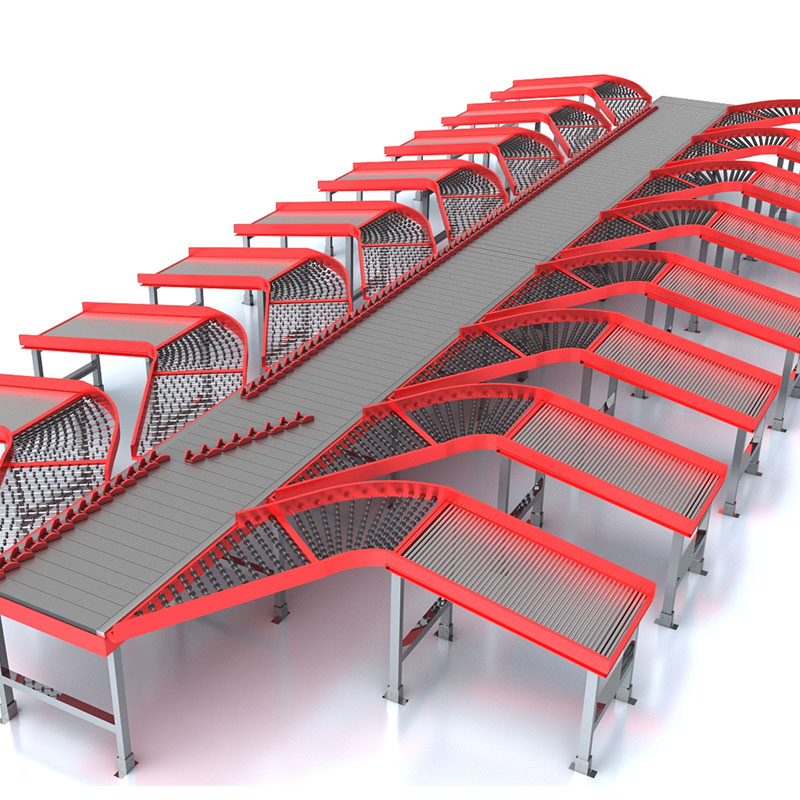

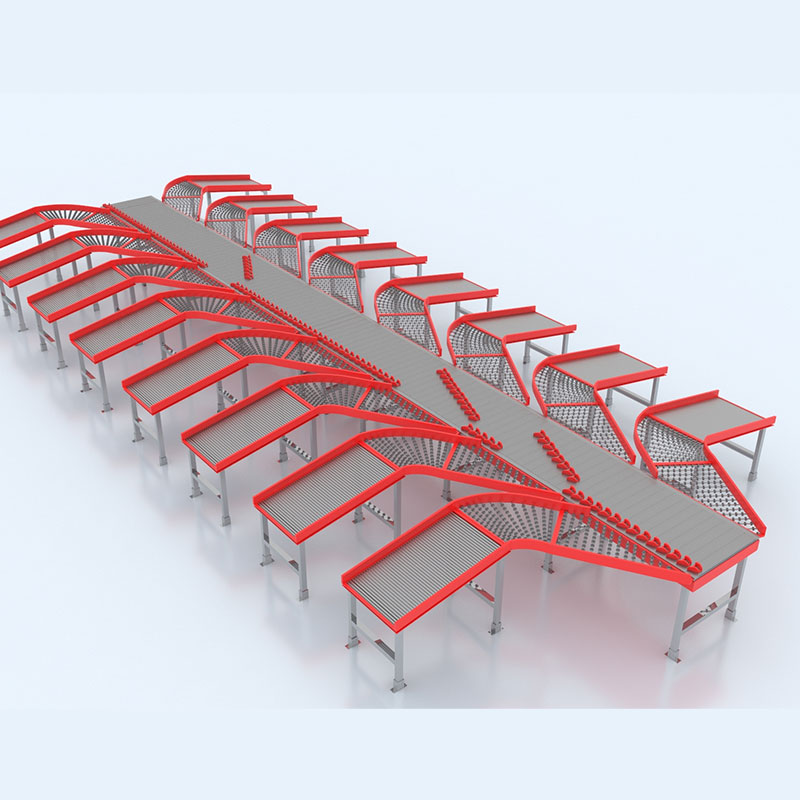

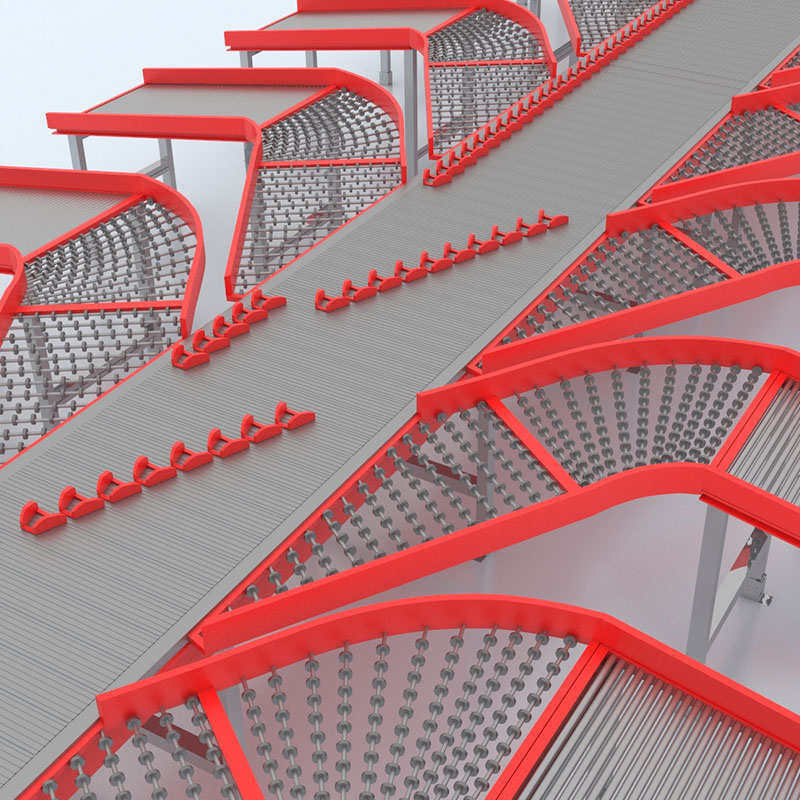

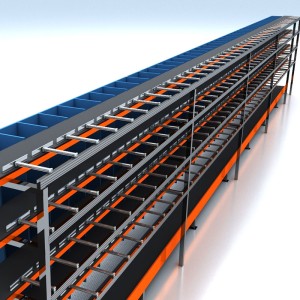

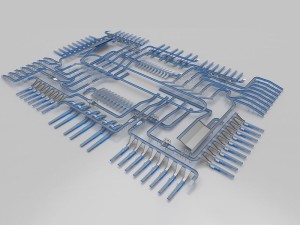

Application method: Through the internal fork, the slider where the corresponding goods are located is moved to the channel where the corresponding chute is located, and several sliders related to the goods drive the goods to slide to one side and enter the chute.

Sliding Shoe Sorter

Description

Descripition

Specification

Solutions

Case

Application Method:

Through the internal fork, the slider where the corresponding goods are located is moved to the channel where the corresponding chute is located, and several sliders related to the goods drive the goods to slide to one side and enter the chute.

Features of the Sliding Shoe Sorter

- High-speed sorting capability: Sliding shoe sorters can quickly handle large volumes of parcels, reaching a high-speed sorting capability of thousands of pieces per hour.

- Highly accurate sorting: Sliding shoe sorter uses a sliding shoe to precisely locate items to their target position and avoid sorting errors.

- Wide range of applications:The sliding shoe sorter is suitable for various items such as parcels, bags, boxes, etc.

- Energy efficient: Sliding shoe sorter is designed to be Energy efficient, which reduces energy consumption and costs.

- Safety and Reliability: Sliding shoe sorters have safety guards, stable load-carrying capacity, and operational reliability to ensure operator safety.

In summary, the features of the sliding shoe sorter include high speed, high accuracy, high performance, a wide range of applications, safety, reliability, etc. It is one of the essential pieces of equipment in modern logistics sorting.

Application Areas of Sliding Shoe Sorter

- Logistics warehousing:It is used for sorting express parcels, goods, etc.

- E-commerce distribution:It can be used for processing, sorting, packing, etc., and e-commerce orders.

- Airport baggage sorting system:It can be used for sorting, dividing, and conveying baggage.

In summary, the sliding shoe sorter has many applications and can be used in almost any scenario where logistics sorting is required. It can improve logistics efficiency and reduce costs.

| Specification | |

Basic Sorting Module | To both left and right sides |

Sorting length | Max: 140m |

Sorting speed | Max: 3.3m/s |

Efficiency | ≥8000 p/h |

Body width for single-side sorting | 856~1356mm (with the increment of 100mm per addition) |

Body width for double-side sorting | 1056~1556mm (with the increment of 100mm per addition) |

Feeding method | Manual |

Feeding efficiency | ≥3000 p/h |

Noise | ≤72dB |

E-commerce Logistics System

Since entering the Chinese market in the 1990s through its main air express and domestic private express processing system business, PGSL has acquired FedEx Beijing Port, DHL Hong Kong Hub, TNT (East China, North China), SF (SF Express National Main Distribution Center), YUNDA (Yunda North China, East China, South China) and other domestic express companies, various distribution center projects have become the inevitable choice for the rapid development of many logistics express companies.

Shopee Dongguan Combined Warehouse

The equipment has reliable safety protection measures, the layout of the field equipment is reasonable, and the cross beam connection between adjacent equipment is added to ensure the overall stability of the equipment. According to the characteristic of the product, the anti-pinch design is implemented.

Cainiao Cixi sorting project

One floor of 151.2m, with 252 carriers in total sorting to both sides; One inbound zone with 6 stations, speed of 2.2m/s and 10,560 PPH in actual use.