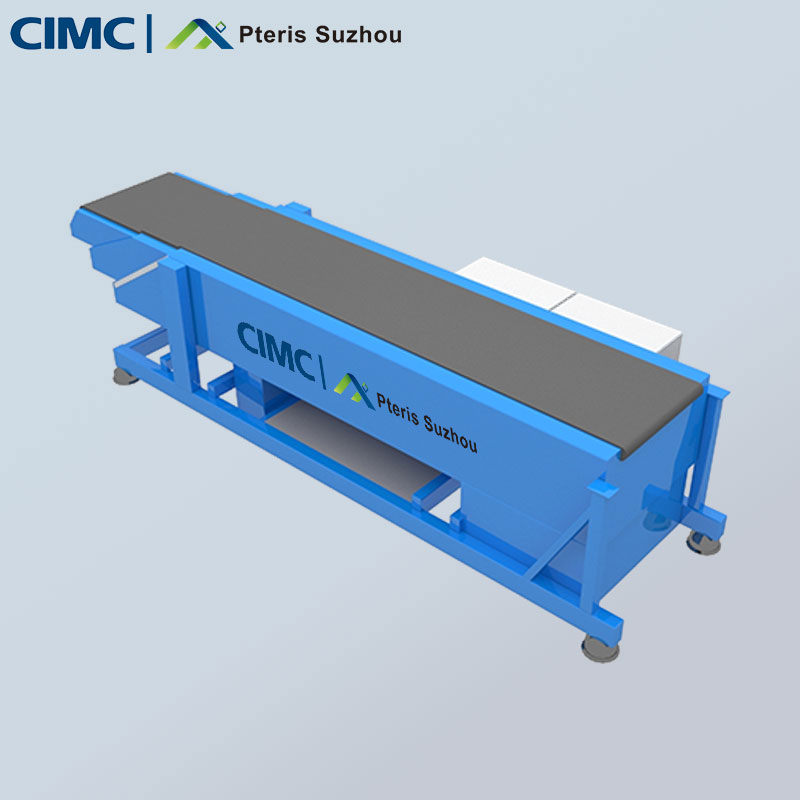

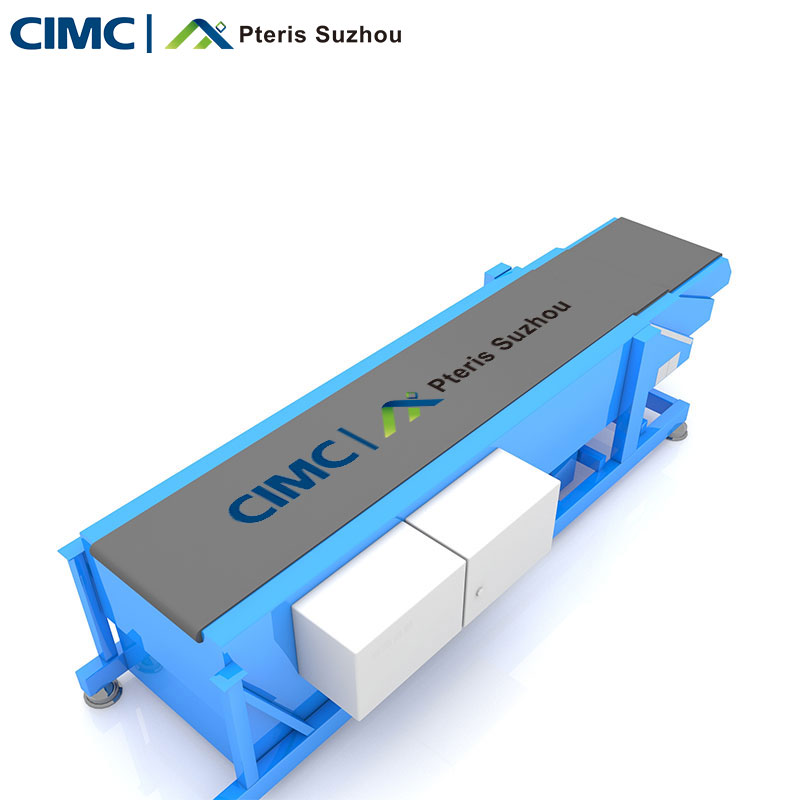

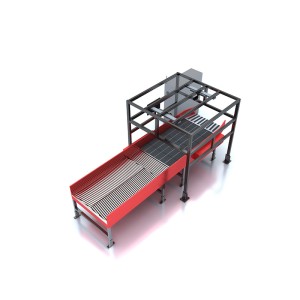

Application method: Telescopic belt conveyor is mainly used in vehicle loading and unloading and logistics conveying systems with telescopic requirements.

Telescopic Belt Conveyor

Description

Descripition

Specification

Solutions

Case

Application Method:

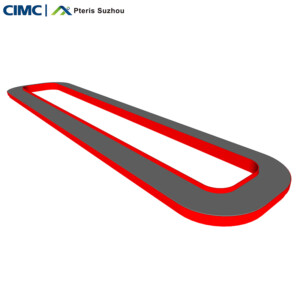

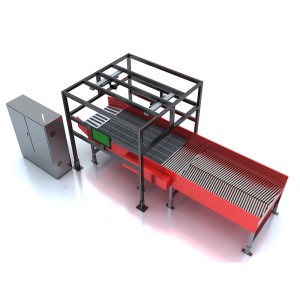

Telescopic belt conveyor is mainly used in vehicle loading and unloading and logistics conveying systems with telescopic requirements. It is a continuous conveying equipment that can change the conveying length and conveying height, and has the characteristics of cantilever conveying.

| Specification | |

| Conveying load | Dynamic load:60KG/M² Static load:200KG/M² |

| Max size of items | 1200*800*700MM |

| Effective width | 600/800MM |

| Conveying height | Depending on the listed equipment |

| Conveying direction | Two-way |

| Conveying speed | 20-35M/MIN |

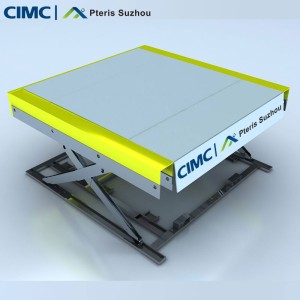

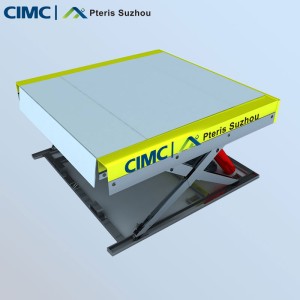

| Lifting method | Equipped with imported hydraulic lifting system |

| Lifting angle | -2.5°~2° |

Express Delivery System Integration

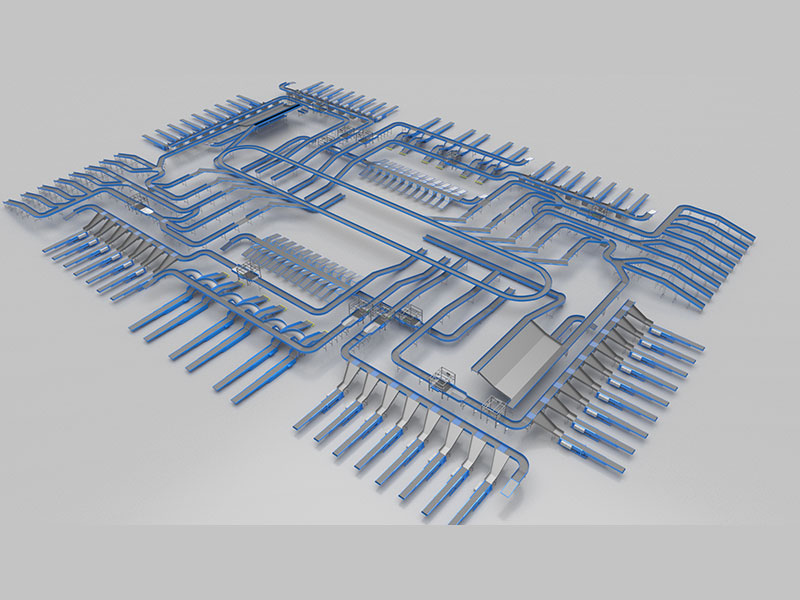

Through the actual situation of the express industry in terms of more stringent requirements for the inbound, unloading, receiving, scanning, X-ray machine security inspection, weighing, unpacking, sorting, packaging, and outbound fast loading of goods, PGSL, With the experience over 150 airport baggage conveying system projects and air cargo terminal projects around the world, has carried out in-depth cooperation with well-known international and domestic express companies. At the same time, according to the actual situation of technology, labor force and national policies in the domestic express delivery industry, it provides automatic and semi-automatic express delivery solutions of different standards for the express delivery industry, and accelerates the transformation and upgrading of customers in the express delivery industry.

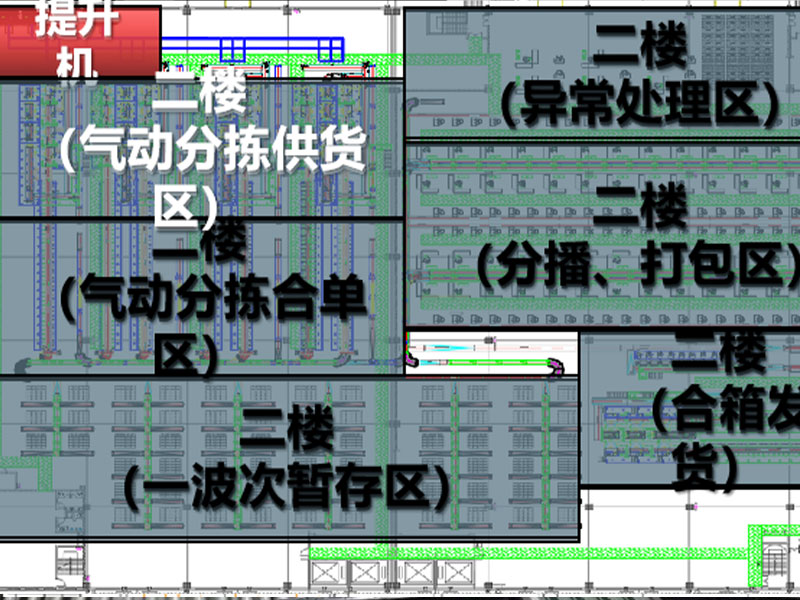

Cainiao Cixi Sorting Project

-2000 meters long conveying system

-Full cycle of feeding, packing, transferring, and sorting are all included One inbound zone with 6 stations, a speed of 2.2m/s, and 10,560 PPH in actual use.

Shopee Dongguan Combined Warehouse

The equipment has reliable safety protection measures, the layout of the field equipment is reasonable, and the cross-beam connection between adjacent equipment is added to ensure the overall stability of the equipment. According to the characteristic of the product, the anti-pinch design is implemented.