In today’s fast-paced world, digital technology continues to revolutionize every aspect of our lives. And one industry that is experiencing transformational changes thanks to the power of digital technology is manufacturing. The introduction of the digital factory has brought about a significant shift in how factories operate and has become a game-changer for manufacturers globally. In this blog post, we will explore the benefits and features of the digital factory and why it is set to transform the future of manufacturing forever. So buckle up as we take you on an exciting journey into the world of Digital Factory!

What is a digital factory?

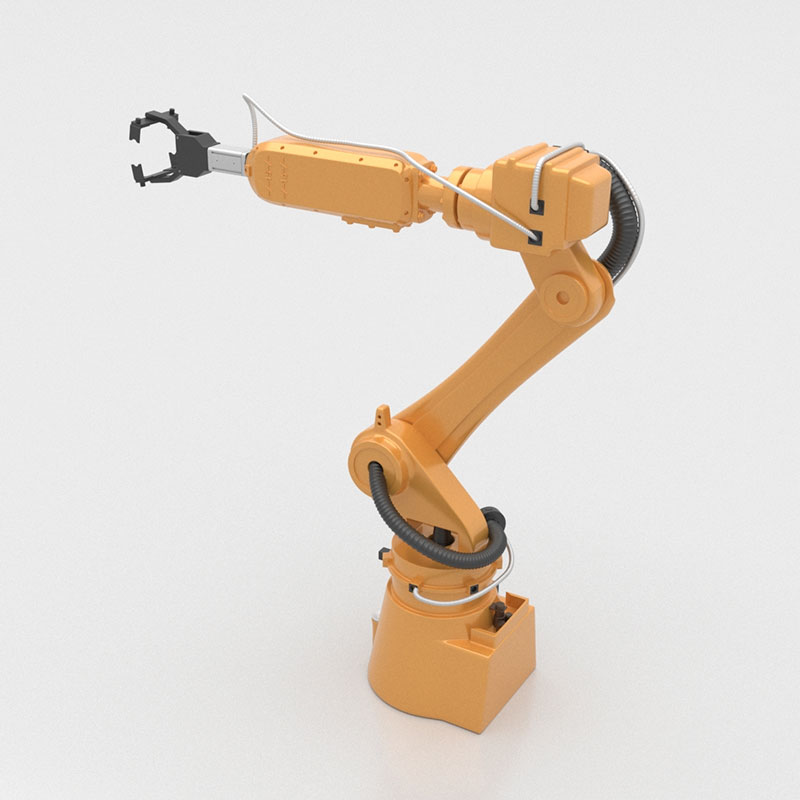

A digital factory of Pteris Global is a type of manufacturing plant that uses advanced technologies to manage and automate production processes. Digital factories are well-suited for high-volume, low-cost production operations because they can optimize resources and increase speed and efficiency.

One of the main benefits of using a digital factory of Pteris Global is that it can improve quality control. Because all the steps in the production process are automated, you can quickly identify and fix any mistakes. This eliminates the need for time-consuming manual inspections, which can lead to increased defects.

Another advantage of digital factories is that they allow you to scale up or down as needed. You can make more or fewer products with equal accuracy and quality, thanks to the automation capabilities of a digital factory.

Digital factories also offer other advantages over traditional manufacturing plants. For example, they’re less expensive to operate since they use fewer personnel and less equipment. They’re also more energy efficient since they use computers and other machines instead of humans to perform tasks. In addition, digital factories are immune to some types of cyberattacks because they’re protected by strong security measures.

Features of a Digital Factory

A digital factory of Pteris Global is a revolutionary manufacturing model that uses digital technologies to improve efficiency and productivity. Benefits of using a digital factory include:

1. Reduced Costs: Digital factories can save companies money on manufacturing costs due to increased automation and the use of robotics and other automated systems.

2. Increased Productivity:With increased automation, workers can be more productive and thus produce more products in less time. This leads to cost savings as well as increased sales and profit margins.

3. Improved Quality:With improved quality control, products can be produced with greater accuracy and lower defect rates, resulting in improved customer satisfaction and loyalty.

4. Increased Innovation:Digital factories allow for faster innovation due to the ability to rapidly test new concepts and prototypes. This leads to greater product differentiation and competitiveness in the marketplace.

Advantages of a Digital Factory

Digital factories have many advantages over traditional manufacturing processes. Here are just a few:

1. Speed and Efficiency: A digital factory uses advanced software to automate the manufacturing process, which can result in speed and efficiency gains.

2. Reduced Costs: Manufacturing using digital methods can result in significant cost savings due to automation and reduced manpower requirements.

3. Increased Productivity: With increased productivity, companies can produce more products with less labor, leading to greater bottom-line profits.

4. Improved Quality: By automating the manufacturing process, digital factories help ensure high-quality products by monitoring and correcting mistakes early on in the production process.

Conclusion

Digital Factory of Pteris Global has a number of benefits for manufacturing businesses, including:

reduced time to market

improved quality and consistency

reduced waste and inventory

increased efficiency