The St. Dyne Project

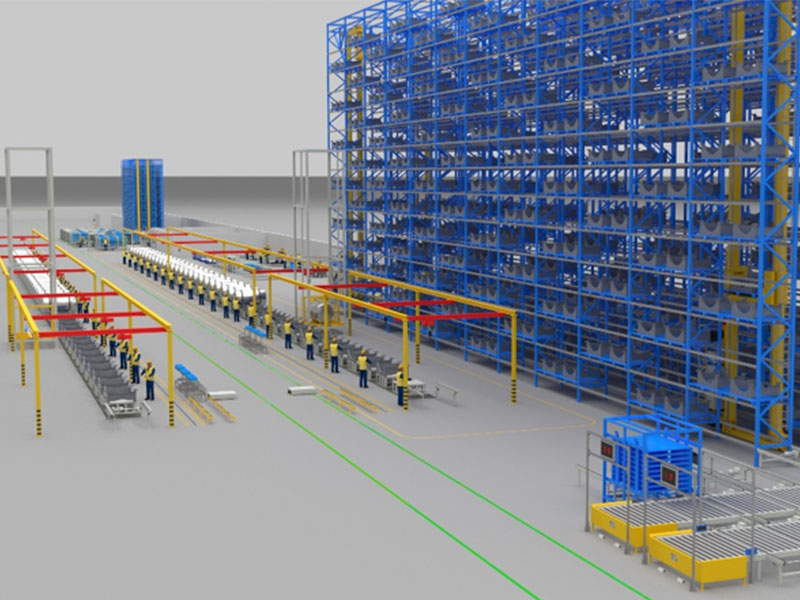

The project includes eight parts: material box storage area, frame storage area, parts picking area, small parts prefabrication area, large parts prefabrication area, second-floor bottle conveying area, AGV picking area, and final assembly production area It consists of a production scheduling system (PCS), material Pulling system (LES), storage equipment Management system (WCS), AGV Path Scheduling system (RCS), and Electronic label Management system (DPS) Through the system equipment to achieve the final assembly order as a pull, to solve the material distribution automation intelligent operation, and has the automatic tracking, real-time update function.